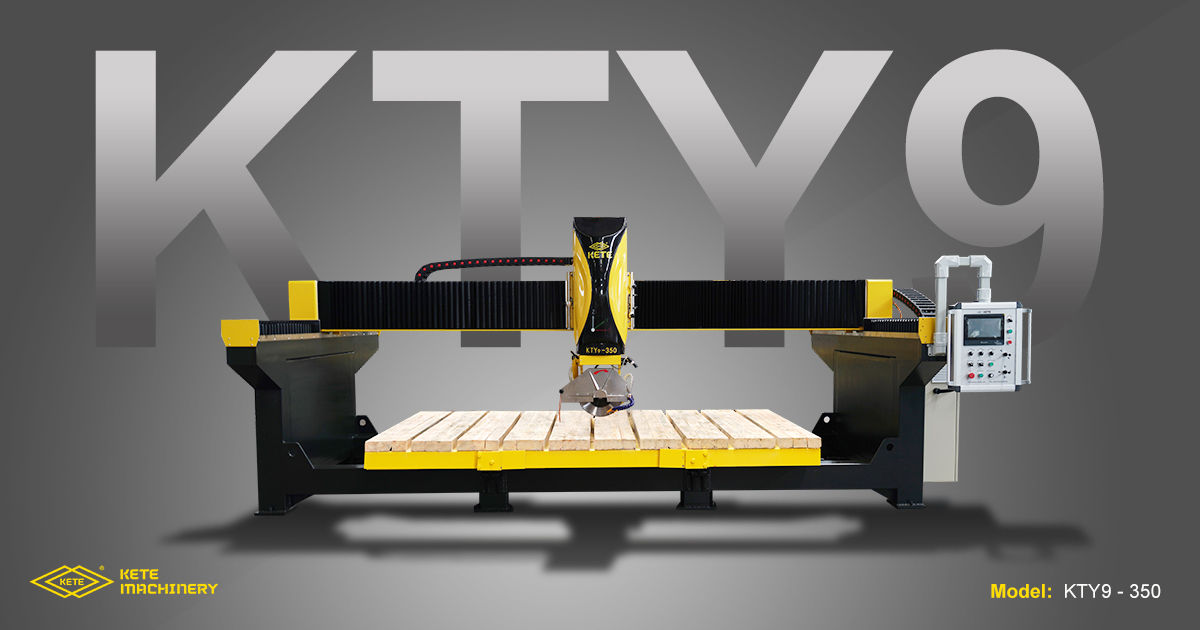

This model features an integraed structure that enhances effciency and precision while minimizing its overall footprint. Its compact and space-saving design ensures easy installation, making it an ideal solution for workshops with limited space. Engineered for high-performance cutting, this machine delivers consistent accuracy and reliability, optimizing productivity in stone fabrication.

This model features an integraed structure that enhances effciency and precision while minimizing its overall footprint. Its compact and space-saving design ensures easy installation, making it an ideal solution for workshops with limited space. Engineered for high-performance cutting, this machine delivers consistent accuracy and reliability, optimizing productivity in stone fabrication.

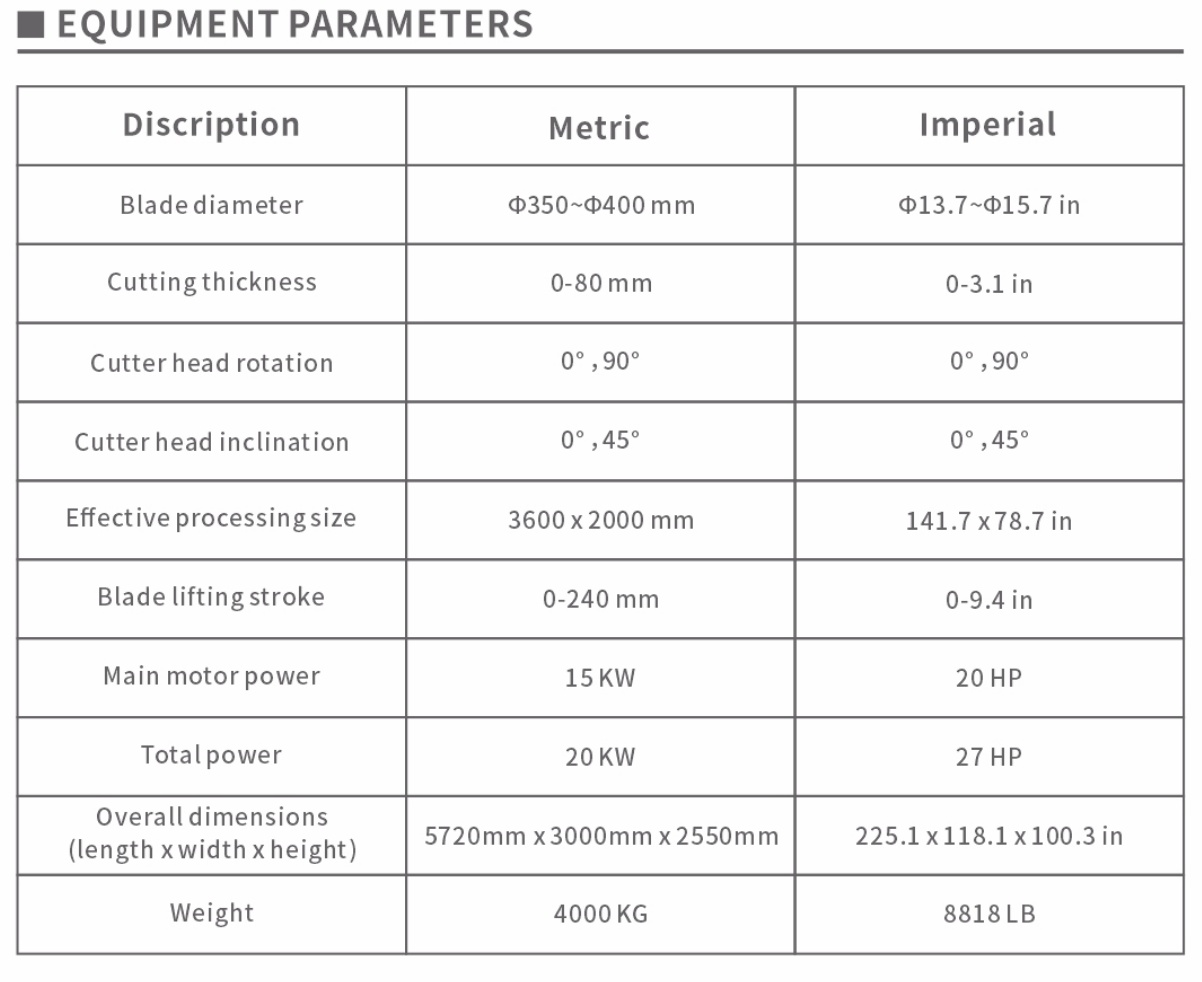

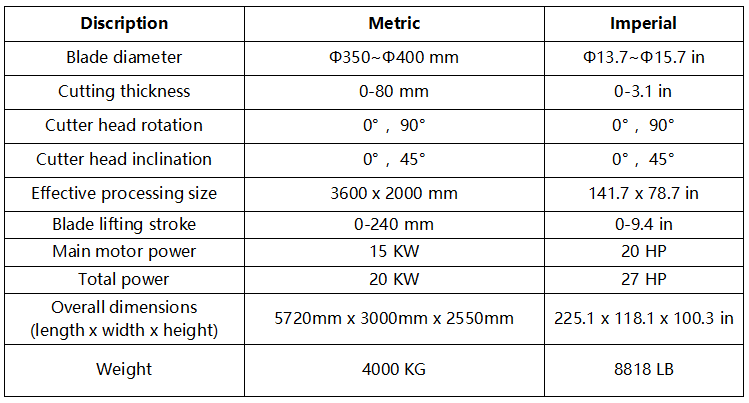

Cutter Head:

● The cutter head is engineered for versatility, capable of rotating a full 90°, enabling precise vertical and horizontal cuts. It also tilts up to 45°, allowing for intricate angled cuts such as bevels and chamfers, making it ideal for complex designs and edge work.

● The 45° chamfering function supports multi-pass incremental cutting, ensuring controlled depth progression for enhanced precision and blade durability.

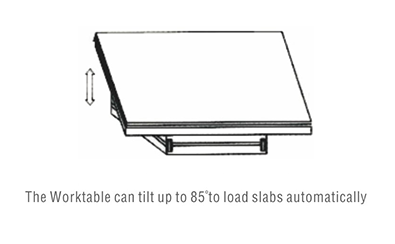

Worktable

● Two worktable configurations are available:

1. Non-rotating: A stable, fixed option for straightforward cutting tasks.

2. Rotating and tilting: This advanced option allows the worktable to rotate 360°, enabling precise positioning of the stone.

●Both types are able to tilt vertically from 0° to 85°, facilitating easy loading and unloading of slabs while accommodating various cutting angles for improved cutting efficiency on thicker materials.

Movement System

● The machine utilizes precision linear guide rails for smooth and controlled movement of the cutting head and beam, ensuring high accuracy in every cut.

● A high-performance servo drive system powers the head and beam, providing rapid acceleration and deceleration, while maintaining stability during motion. This results in more precise, consistent cuts, even at high speeds.

● The machine head lifting system features a ball screw structure with servo motor positioning, ensuring high precision and rapid movement for optimized cutting performance.

Motor

● A high-power, water-cooled motor drives the cutting process, delivering smooth, uninterrupted cutting across a wide range of materials. The motor's integrated water-cooling system ensures optimal temperature control, protecting the motor from overheating and extending its operational life during long cutting sessions.

Operation

● The machine features an intuitive control system designed for ease of use. The operator can quickly switch between different cutting modes, such as orthogonal cutting for straight cuts and chamfering for angled cuts. These modules enable fully automated processing, reducing manual input and increasing production efficiency.

Tool Adjustment:

● An electronic handwheel allows for precise fine-tuning of the cutting tool, ensuring accurate positioning and depth control. This feature enhances the machine's ability to handle intricate cutting tasks that require minute adjustments.