The Wire Gang Saw delivers superior cutting performance with eight key advantages: It enables real-time remote monitoring via IoT, increases material yield by over 95% with a 0.5mm cutting seam, and can produce ultra-thin slabs down to 2mm. The machine ensures high surface quality, reduces energy use by 10–20% and water consumption by over 20%, operates with minimal vibration for enhanced safety, cuts waste residue by 80% and noise by over 40%, and features a compact design saving more than 30% in floor space.

The Wire Gang Saw delivers superior cutting performance with eight key advantages: It enables real-time remote monitoring via IoT, increases material yield by over 95% with a 0.5mm cutting seam, and can produce ultra-thin slabs down to 2mm. The machine ensures high surface quality, reduces energy use by 10–20% and water consumption by over 20%, operates with minimal vibration for enhanced safety, cuts waste residue by 80% and noise by over 40%, and features a compact design saving more than 30% in floor space.

Eight Key Advantages of the Wire Gang Saw:

Smart Monitoring – Integrated with remote IoT technology, allowing real-time tracking of cutting operations anytime, anywhere.

Maximized Material Yield – Ultra-narrow 0.5mm cutting seam increases material utilization to over 95%, improving yield by 15–20% compared to traditional methods.

Ultra-Thin Cutting – Single-wire saw is capable of processing ultra-thin slabs as thin as 2mm with precision.

Superior Quality – High-precision cutting ensures a smooth surface, reducing waste and minimizing the time required for grinding and polishing.

Energy Efficient – Reduces power consumption by 10–20% and lowers water usage by more than 20% compared to traditional machines.

Enhanced Safety – Minimal mechanical vibration, ensuring stability during cutting.

Eco-Friendly – Reduces waste residue by over 80% and cuts noise levels by more than 40%, promoting a greener work environment.

Space-Saving Design – Optimized footprint reduces floor space requirements by more than 30%, maximizing workshop efficiency.

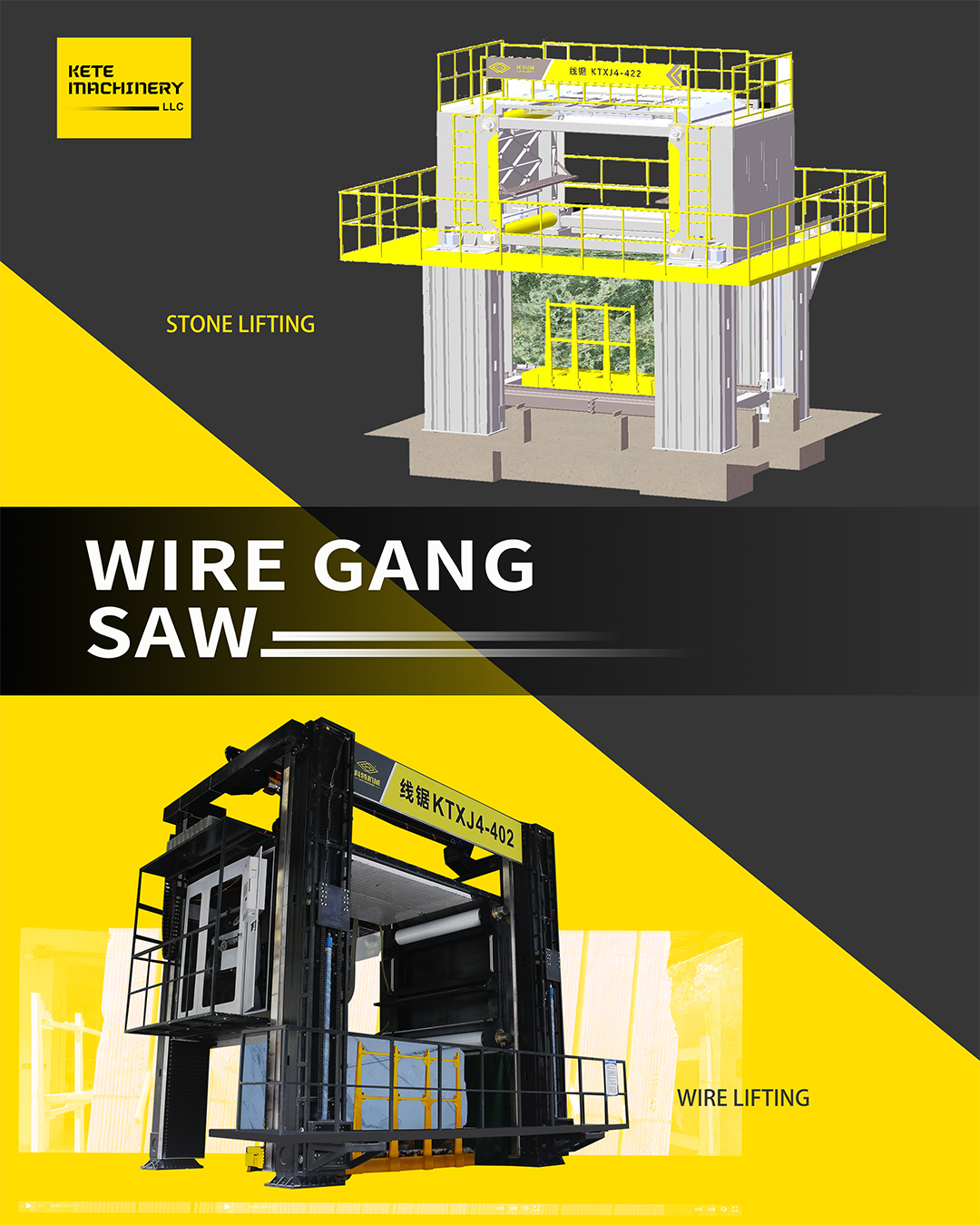

| TECHNICAL PARAMETER | ||

| Model | ||

| KTXJ4-402 | KTXJ4-422 | KTXJ4A-422 |

| Maximum processing size (L×W×H) mm | ||

| 3400×2000×2200 | 3400×2200×2200 | 3400×2200×2200 |

| Processing slab thickness (mm) | ||

| 10–30 | 10–30 | 10–30 |

| Diamond wire diameter | ||

| Φ0.3–0.8 | Φ0.3–0.8 | Φ0.3–0.8 |

| Maximum wire storage capacity | ||

| 30km | 30km | 30km |

| Wire working speed | ||

| 0–20m/s | 0–20m/s | 0–20m/s |

| Lifting method | ||

| Linear lifting | Linear lifting | Stone lifting |

| Lifting speed | ||

| 0–210mm/min | 0–210mm/min | 0–210mm/min |

| Water consumption | ||

| 20m³/h | 20m³/h | 20m³/h |

| Total power | ||

| 300kw | 300kw | 300kw |

| Dimensions (L×W×H) mm | ||

| 7200×5200×640 | 7200×5400×6400 | 7500×5400×6800 |

| Total weight | ||

| 30t | 30t | 30t |